- Johnny's Research Farm | Breeding, Trialing, Selection & Quality Assurance

- Johnny’s OP Stewardship Project: Restoration of ‘Hungarian Hot Wax’ Pepper

- Open-Pollinated Revival Project: 3 Improved OP Heirloom & Heritage Tomatoes

- A Brief History of Tool Development at Johnny's | Planting the Seed of a Small-Scale Farming Revolution

- Classical Plant Breeding at Johnny's | by Rob Johnston, Jr, Plant Breeder (Retired) & Founder of Johnny's Selected Seeds

- 5 JSS-Bred Varieties Introduced by Rob Johnston, Jr., Plant Breeder & Founder (Retired), Johnny's Selected Seeds

- 3 for 2020: New Johnny-Bred Stories by Rob Johnston, Jr. | ‘Starry Night,’ ‘Citrine’ & ‘Pipsqueak’

- Classical Plant Breeding at Johnny's Selected Seeds | Infographic

- About Johnny's Variety Trialing Program

- Seed Variety Trialing – Why Try Something New?

- Seed Variety Trialing at Johnny's Selected Seeds | Infographic

- How to Conduct a Scale-Appropriate Trial on Your Own Farm

- All-America Selections Award-Winning Varieties Bred by Johnny's | Spec Sheet

- Varieties Bred by Johnny's | 4-pp Brochure

- About Johnny's | PDF

- Johnny's Announces 'Rhubarb Supreme' | New Bolt-Resistant Strain of a Favorite, Open-Pollinated Swiss Chard | Press Release

- Johnny's Corno di Toro Peppers Rule | Press Release

- Pea Selection at Johnny's | The Story of 'Sugar Ann' Snap Pea

- The Johnny's Advantage | PDF

- Video: Classical Plant Breeding at Johnny's

- Video: 'Cherry Bomb' | JSS-Bred Organic Cherry x Grape Tomato from Johnny's

- Video: Johnny's Trialing Program

- Video: Hand-Pollinating Peppers at Our Research Farm | Classical Plant Breeding at Johnny's Selected Seeds

- Video: 'Clementine' | The Tangerine-Colored, Organic Cocktail Tomato from Johnny's Breeding Team

- Johnny’s Selected Seeds Observes 50th Anniversary | Press Release

- Johnny's Welcomes Kevin L Cook, PhD as VP of R&D | Press Release

- Restoration of OP 'Hungarian Hot Wax' Pepper | Exclusively from Johnny's Selected Seeds

- Farm Tours of Johnny's Research & Trialing Farm

A Brief History of Tool Development at Johnny's

All images & content © Johnny's Selected Seeds. All Rights Reserved.

Planting the seed of a small-scale farming revolution

“ The man or woman who has converted material into needed products via tools and skills has matured in the process. ”

— Helen Nearing

The Good Life: How to Live Sanely and Simply in a Troubled World (1954)

On the verge of its 50th year at the time of this writing, Johnny's was well into its third decade as a seed breeder and purveyor before it began to offer much in the way of tools for farming. From the outset the objective was to create thoughtful and purposeful tools designed for professional direct-market farmers but with the kind of utility that any home gardener could appreciate and apply — tools of lasting quality, well-crafted and guaranteed for their durability.

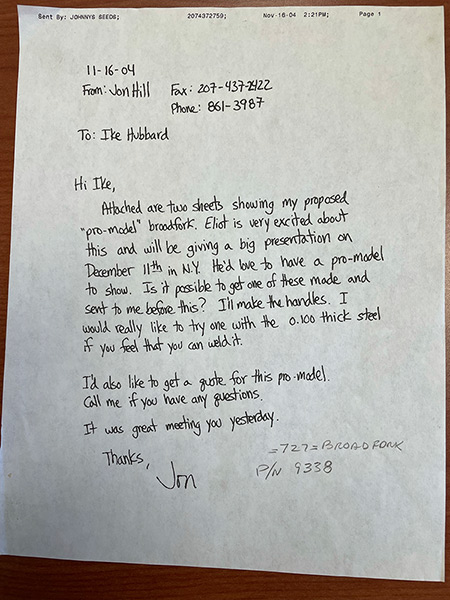

The story behind the tools section of the catalog began with a collaboration between Johnny's founder Rob Johnston, his colleague Eliot Coleman, and Jon Hill, a Maine-based mechanical engineer who served as the company's Tools and Accessories Manager in the early 2000s. Jon connected Eliot with manufacturing partners and inventors Art Haines, an independent Maine-based automation engineer and Ike Hubbard, an industrial engineer based in Jonesport, Maine. Their collective ingenuity is behind a number of tools that Johnny's sells to growers to this day.

To sketch in some background, Eliot had come to Harborside, Maine in the mid-1960s and established the renowned Four Season Farm, where vegetables are grown year round. Over the 60 years since Coleman's move to Maine, many small- to midscale farmers and gardeners have come to hew closely to his script for four-season food production, as laid out in his bestselling books, The New Organic Grower, Four-Season Harvest, and The Winter Harvest Handbook.

One leitmotif in his approach was the 30-inch bed row system. Eliot sought to integrate efficiency with ergonomics by creating a suite of tools expressly for prepping, seeding, and harvesting a 30-inch-wide row of closely-spaced crops such as brassicas, mesclun, carrots, radishes, salad turnips, scallions, and spinach — rows just wide enough to reach across.

One of the resultant tools was a better broadfork, which subsequently evolved into a full line of broadforks for various soil types and applications. Another was a small cultivator that could replace a heavier rototiller, and a third was a 15-inch-wide seeder — all tools that would allow market gardeners to prep and seed 30-inch beds more quickly, ergonomically, and profitably.

Till, prep, seed, and harvest

— Ike Hubbard, Proprietor, Hubbard Rake, Jonesport, Maine

“ We know a tool’s success is only as good as the grower’s success in using it. ”

— Jen Goff, Product Manager, Tools & Supplies

But to achieve that particular vision in the mid 2000-noughts was no mean feat. It required Eliot, Jon, Art, and Rob to work hand-in-glove. "We would meet with Rob every week about the things that people wanted developed," recalls Jon. "I think it was partly to keep me on track, but more importantly to make sure the tools stayed on track, within the company's mission, making sure we were helping growers grow. He was definitely focused on that, and not on becoming just another gardener supply company that sells everything you can think of, like ceramic toadstools. We were always consulting with him on all of these things."

"In early 2006 broadforks weren't new," says Canadian grower, author, and market-farming educator JM Fortier, "but the 727 broadfork was an improvement upon all others on the market." This two-handled, deep-tillage tool has 7 parabolically curved tines spaced 4 inches apart, for a total width of 27 inches. The 727 is now available in two versions: the 2006 model for aerating regular soils and a second, more robust model for working rocky, compacted hardpan. The latter was developed during Adam Lemieux's lengthy tenure as Johnny's Tools and Supplies Product Manager and released in 2015, and the full line is still manufactured Down East at Hubbard Rake.

A battery-run micro-cultivator

— Art Haines, Manufacturing Partner and Industrial Process Engineer

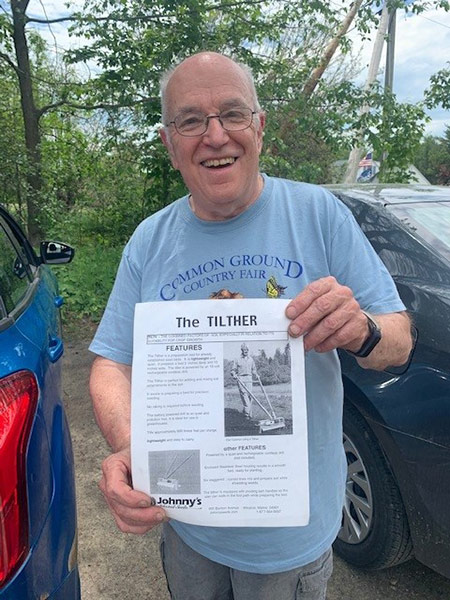

"Then the Tilther and the Six-Row Seeder revolutionized the game," JM continues. "It was the first time such highly precise tools had become available for market gardeners," he notes.

"The Tilther was the biggest challenge," says Jon. "We were trying to make it strong enough to hold up in the environment where it's used, but make it lightweight, portable, and the right tool for just the top two inches of soil. You can hit some really hard things in the top two inches of soil, so it had to be made robust. The aluminum frame and stainless steel shroud of the first working model did the job right out of the gate."

The idea behind the Tilther is that following aeration with the broadfork, the beds can be prepped for seeding by working only the top two inches of the soil. This, unlike rototillers, allows the grower to avoid unearthing the persistent weed seed bank while incorporating amendments such as compost, rock powders, alfalfa meal, and greensand. Powered by an electric drill, the Tilther has six staggered, curved stainless-steel tines that shred weeds and roots. The entire 15-inch width is perfect for making two passes, up and the down the 30-inch bedrow. Because it's powered by a portable electric drill, it is highly maneuverable, ecologically low-impact, and — best of all — quiet.

3 • Level, Firm, and Seed

Here is where the Six-Row Seeder enters the process. The design was based off of the Four-Row Seeder (made by Sembdner in Germany) but adapted expressly to sow six, closely spaced rows at a time, dimensionally gauged for pushing one pass up a 30-inch-wide bed and a second pass back down the other, with no need to roll the bed before planting or afterward.

Art Haines provides some of the background on the concept. "Eliot wanted 2¼-inch spacing, with four different seed sizes. We went with six rows, put rollers on it because we wanted it to roll the bed after seeding, and we wanted it to have a variable pitch, so you can change the spacing of the seeds. That was key." And like all three of the implements, the seeder's design is coupled with solid construction materials, including white ash handles.

Clinching the whole process is the tenacity to seek out and examine improvements to the tools. The goal is to make them more useful and affordable to customers — without permitting parsimony in manufacture to trump value in the growers' hands. An illustration of the ability to take a good thing and make it better is given by the recently rereleased Six-Row Seeder, Second Edition.

"It was an evolution, though," Art qualifies. "First I built a prototype," and, with the help of a grant from the Maine Technology Institute (MTI), a publicly funded, nonprofit corporation established in 1999 to offer assistance for early-stage capital and commercialization efforts, brought it to production. "We had a plastic seed shaft on it, but it was too flexible — I think it was something better than PVC — it might have been engineering plastic of some type. So we went to stainless steel for that. I remember, too, that we had trouble with the rubber belt slipping. We had three miniature pulleys to connect the seed shaft to the spindle, so we went to double the size of the pulleys and it improved the traction. Then it then stayed the same — for years."

"Just last year," relays Art, "I worked on the upgrade with Brad Waugh," Johnny's Mechanical Product Design and Outsourcing Engineer. "We put spikes on the wheels, and it has a better handle now, using a ferrule to connect it with the body." Brad adds, "We explored but discarded several variations in the redesign process, when finding they did not provide the balance of function and value we know our growers require. Much of our examination was on leveraging different manufacturing processes to lower cost and increase efficiency in both assembly and usage."

This year Johnny's came out with version 2 of the six-row and so far, growers are appreciating the improvements. The tool team couples collaborative inventiveness with close listening to feedback from customers who work hard in the field and rely on dependable tools for their success. With their ear to the ground, the team then aligns itself with the company's research team, farm crew, and trial partners to field-test every one of its products with the necessary rigor to ensure the quality Johnny promises.

Growth & Change: Two Constants

"We know a tool's success is only as good as the grower's success in using it," notes Jen Goff, the Product Manager of Tools and Supplies at Johnny's nowadays. "We took on the redesign project knowing that we had a good design — the first Six-Row Seeder was one of our best-selling products — but there were definitely a few areas for improvement."

The tools team has expanded its offerings considerably since its early days, but the line remains tightly curated. In the interim since Jon's time, there followed a dozen years' growth under the aegis of Adam Lemieux as Tools and Supplies Manager. In passing on the entrepreneurial torch, Adam notes, "I have been extremely fortunate to work with industry icons like Eliot and many others. But what has been most rewarding over the last decade has not been the increasing numbers; it has been in developing products that make a difference and really help farmers."

Equally instrumental was that year after year, Rob always found time to meet and partner with individuals whose vision dovetailed so well with his own. If the Six-Row Seeder Second Edition is any indication, Johnny's will continue in the next 50 years to bring new tools to growers of all abilities, with the same commitment, applying the best possible materials to a sustainable balance between great design, affordability, and longevity.

Learn More

Interested in learning more about growing methodology, tools & supplies?